收稿日期: 2023-03-15

修回日期: 2023-05-01

网络出版日期: 2023-11-21

基金资助

国家重点研发计划项目“新型高效冶金生物反应器研制与示范”(2022YFC2105302)

Arsenic Conversion During Pre-Oxidation Treatment of Gold Ores

Received date: 2023-03-15

Revised date: 2023-05-01

Online published: 2023-11-21

陈国民 , 杨洪英 , 陈彦臻 , 张广积 . 金矿预氧化处理过程中砷的转化[J]. 黄金科学技术, 2023 , 31(5) : 865 -872 . DOI: 10.11872/j.issn.1005-2518.2023.05.043

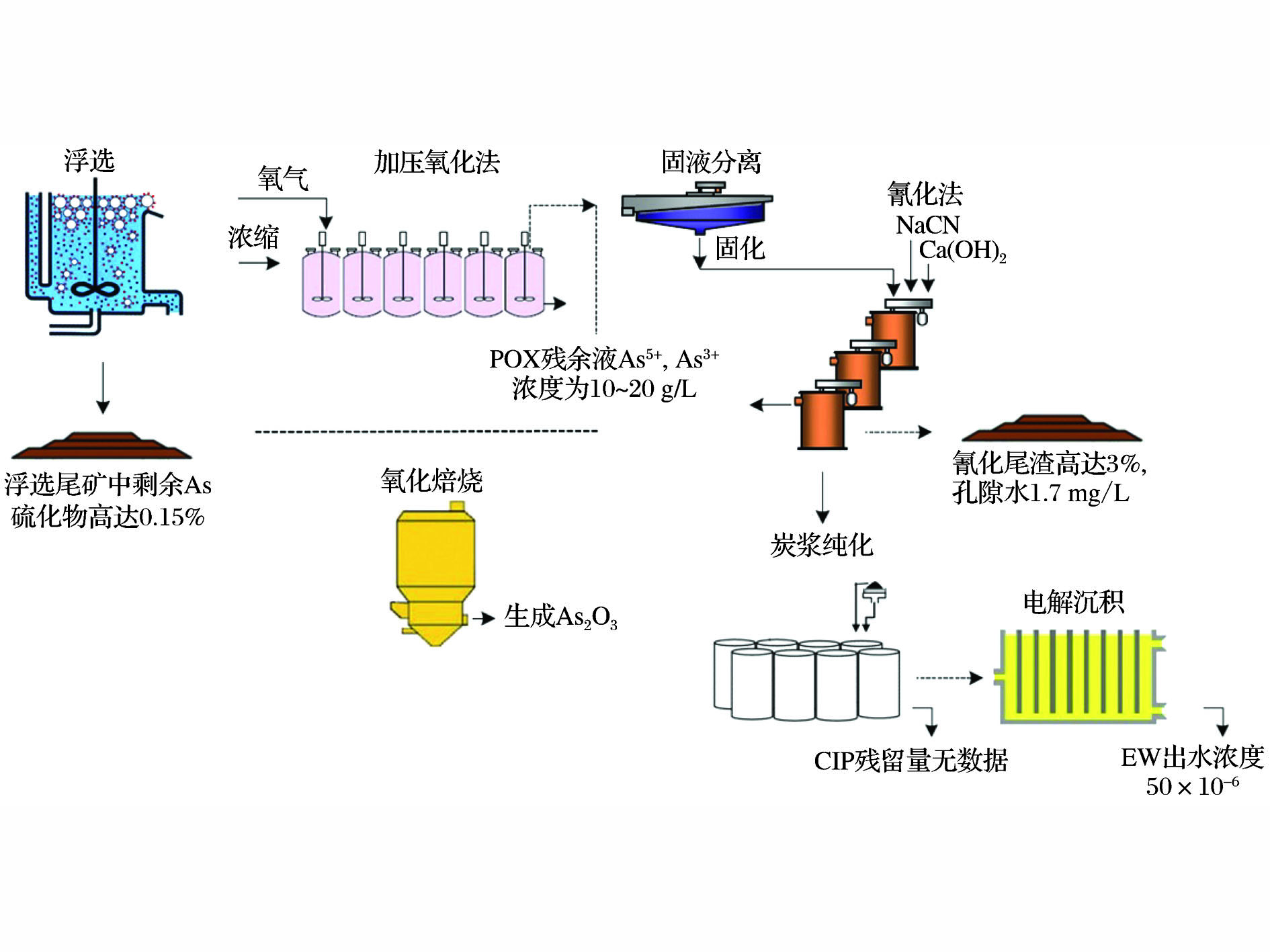

The composition of arsenic-bearing refractory gold mine is complex,in which gold is usually encapsulated by arsenopyrite and arsenian pyrite.Arsenic is a poisonous element,which is harmful to human health and has adverse effects on the ecological environment.At the same time,the arsenic-bearing ores can lead to excessive consumption of cyanide and affect cyanide leaching of gold.Therefore,the arsenic-bearing refractory gold ores need to be pre-oxidized before cyanide leaching.The transforming pathway and final form of arsenic have an important effects on the pre-oxidation treatment of arsenic-containing refractory gold ore.At present,there are three pre-oxidation methods for refractory gold ores,namely roasting process,pressure oxidation and bio-oxidation method.Roasting is a proven technology,which can comprehensively recover copper and arsenic,but it is difficult to avoid the release of arsenic in this process.The pressure oxidation is an environment-friendly process that can achieve high gold recovery,but the expensive pressure reactor used in this process will lead to a high capital cost.Bio-oxidation method can obtain a recovery rate close to that of the pressure oxidation method,and the equipment investment cost is much lower than that of the pressure oxidation method.However,the bio-oxidation reaction is slow and a longer residence time is needed.The long residence time and the low efficiency of bio-oxidation treatment,especially the slow oxidation and decomposition rate of low-arsenic minerals,restricts its further development.It may face competition from pressure oxidation in the future.However,if it can be combined with roasting process,it is possible to improve the roasting process with its own environmental advantages in arsenic treatment to form a gold ore treatment technology with both advantages of clean production and efficient treatment.The advantages and existing problems of these pre-oxidation methods for refractory gold ores were reviewed in this paper with emphasis on the conversion of arsenic.Considered the development status of Chinese gold industry and the requirements of environmental protection,the basic development direction of pre-oxidation for refractory gold ores in the future was prospected.With the wide application of arsenic-containing refractory gold ores,the decomposition of arsenic-containing ores by pre-oxidation has become a common process for gold extraction.The pre-oxidation process should consider not only the gold extraction efficiency,but also the safe disposal of arsenic-containing waste.With the increasing of environmental concerns,the requirements of cleaner production even exceed the requirements of production efficiency.The common development of clean production and efficient production is the main trend of current development.

| null | Asselin E,2016.Chapter 41-Developments in Arsenic Management in the Gold Industry [M]. Amsterdam:Elsevier. |

| null | Boboev I R, Tabarov F S,2021.Removal of scorodite arsenic from gold ore in the form of As2S3 and As4S4 [J].Hydrometallurgy,199:105530. |

| null | Cao Xin, Lei Li, Wang Zhiwei,et al,2021.Research on the roasting process of micro-fine grain refractory gold ore with high arsenic and high carbon content in North Sichuan [J].Gold,42(5):52-55. |

| null | Chéron J, Loubière C, Delaunay S,et al,2020.CFD numerical simulation of particle suspension and hydromechanical stress in various designs of multi-stage bioleaching reactors[J].Hydrometallurgy,197:105490. |

| null | Cui Binggui, Kang Guoai, Chen Fashang,et al,2017.Experimental research on bio-oxidation pretreatment of high arsenic content gold concentrates and its application [J].Gold,38(8):56-58. |

| null | Cui R C, Yang H Y, Chen S,et al,2010.Valence variation of arsenic in bioleaching process of arsenic-bearing gold ore[J].Transactions of Nonferrous Metals Society of China,20(6):1171-1176. |

| null | Cui Richeng, Yang Hongying, Fu Yao,et al,2011.Biooxidation-cyanidation leaching of gold concentrates with different arsenic types[J].The Chinese Journal of Nonferrous Metals,21(3):694-699. |

| null | Fang Zhaoheng, Xia Guangxiang, Shi Wei,et al,2001.Technological study on gold extraction from a refractory gold concentrate containing high As and Sb[J].Gold Science and Technology,9(3):28-35. |

| null | Fujita T, Taguchi R, Abumiya M,et al,2008a. Novel atmospheric scorodite synthesis by oxidation of ferrous sulfate solution.Part I[J].Hydrometallurgy,90(2/3/4):92-102. |

| null | Fujita T, Taguchi R, Abumiya M,et al,2008b. Novel atmospheric scorodite synthesis by oxidation of ferrous sulfate solution.Part II.Effect of temperature and air[J].Hydrometallurgy,90(2/3/4):85-91. |

| null | Ke Jiajun,2005. Handbook of Hydrometallurgy[M].Beijing:Metallurgical Industry Press. |

| null | Ke Pingchao, Liu Zhihong, Liu Zhiyong,et al,2016.Research status on composition,structure,and leaching stability of an arsenic solidification mineral scorodite[J].CIESC Journal,67(11):4533-4540. |

| null | Lei Zhanchang, Yu Jie, Ma Hongrui,2014.Statue and development of pretreatment technology for the refractory gold ore[J].Morden Mining,30(5):23-24,33. |

| null | Leist M, Casey R J, Caridi D,2000.The management of arsenic wastes:Problems and prospects[J].Journal of Hazardous Materials,76(1):125-138. |

| null | Liu Hanzhao,1993.Discussion on gold extraction technology of ultrafine fine gold ore with rich arsenic carbon[J].Multipur-pose Utilization of Mineral Resources,1(3):8-16. |

| null | Liu Junzhuang, Huang Wanfu,2010.Progress of gold leaching process from the high arsenic gold ore[J].Modern Mining,26(10):26-29. |

| null | Liu Shugen, Tian Xueda,2005.Situation and prospect on treating of arsenic-containing solid waste[J].Hydrometallurgy of China,23(4):183-186. |

| null | Martin D V D B, Heather E J, Michael J P,2018.Arsenic mobility and characterization in lakes impacted by gold ore roasting,Yellowknife,NWT,Canada [J].Environmental Pollution,234:630-641. |

| null | Meng Yuqun, Wang Longbao,2001.Roasting pretreatment of refractory gold concentrate at low temperature and low sulphide oxidized rate[J].Nonferrous Metals,53(4):29-32,40. |

| null | Nazari A M, Radzinski R, Ghahreman A,2017.Review of arsenic metallurgy:Treatment of arsenical minerals and the immobilization of arsenic[J].Hydrometallurgy,174:258-281. |

| null | Ng W S, Liu Y, Chen M,2022.The effect of curing on arsenic pre-cipitation and kinetic study of pressure oxidation of pyrite and arsenopyrite[J].Minerals Engineering,185:107675. |

| null | Rossi G,1999.The design of bioreactors[J].Process Metallurgy,9(2):61-80. |

| null | Samouhos M, Peppas A, Bartzas G,et al,2021.Arsenic release through refractory gold ore processing. Immobilization and decontamination approaches[J].Current Opinion in Environmental Science and Health,20:100236. |

| null | Shen Cailong, Jia Yan, Chen Yanzhen,et al,2022.Research progress of chemical engineering technology in the process intensification of biohydrometallurgy[J].The Chinese Jou-rnal of Process Engineering,22(10):1349-1359. |

| null | Shu Bo, Zhou Shang, Zhang Baohui,et al,2020.Treatment of arsenic containing waste acid and development of arsenic fi-xation technology in nonferrous smelting[J].Conservation and Utilization of Mineral Resources,40(3):12-20. |

| null | Strauss J A, Bazhko V, Ventruti G,et al,2021.Arsenic behavior during the treatment of refractory gold ores via POX:Characterization of Fe-AsO4-SO4 precipitates[J].Hydrometallu-rgy,203:105616. |

| null | Wang G H, Xie S B, Liu X X,et al,2018.Bio-oxidation of a high-sulfur and high-arsenic refractory gold concentrate using a two-stage process[J].Minerals Engineering,120:94-101. |

| null | Wang Jinsheng, Lian Haiying, Jian Linglan,2013.Arsenic recovery from roasting fumes of gold smelting [J].Gold,34(7):65-68. |

| null | Wang Lijun, Luo Yuanhui, Gao Hongshan,et al,2005.Research on encapsulation of roasted refractory gold concentrate [J].Chinese Journal of Rare Metals,29(4):424-428. |

| null | Wang Shuai, Li Chao, Li Hongxu,2014.Research progress of pretreatment technologies of refractory gold ores [J].Gold Science and Technology,22(4):129-134. |

| null | Wen Q, Yang X, Yan X,et al,2022.Evaluation of arsenic mineralogy and geochemistry in gold mine-impacted matrices:Speciation,transformation,and potential associated risks [J].Journal of Environmental Management,308:114619. |

| null | Wiertz J V, Mateo M, Escobar B,2006.Mechanism of pyrite catalysis of As(III) oxidation in bioleaching solutions at 30 ℃ and 70 ℃ [J].Hydrometallurgy,83(1/2/3/4):35-39. |

| null | Wu Hao,2021.The Theory and Process Research of Alkaline Pressure Self-leaching of Arsenic Bearing Refractory Gold Ore[D].Beijing:University of Science and Technology Beijing. |

| null | Xi Xinyue, Cui Yiqi, Wang Yubo,et al,2022.Research progress on influence of arsenic-bearing sulfide minerals on gold ore leaching [J].Industrial Minerals and Processing,51(4):10-14,25. |

| null | Xia Guangxiang, Fang Zhaoheng, Shi Wei,2001.Gold extraction technology and prospect of refractory gold ores [J].Non-Ferrous Smelting,30(4):31-34. |

| null | Xia Guangxiang, Shi Wei, Tu Taozhi,et al,1996.Study on pretreatment of arsenic-containing refractory gold ores with ammonia leaching[J].Gold,17(10):28-34. |

| null | Xiong Min, Shi Guanyong, Tian Lei,et al,2022.Preparation of metallic arsenic from calcium arsenate by carbon thermal roasting reduction [J]. Chinese Journal of Engineering,44(5):886-893. |

| null | Yu R L, Wu F D, Chen A,et al,2015.Effect of mixed moderately thermophilic adaptation on leachability and mechanism of high arsenic gold concentrate in an airlift bioreactor[J].Journal of Central South University,22(1):66-73. |

| null | Zhang Lei, Guo Xueyi, Tian Qinghua,et al,2021.Research progress and industrial application of pretreatment methods for refractory gold ores [J].Gold,42(6):60-68. |

| null | Zhang Yuxiu, Guo Degeng, Li Yuanyuan,et al,2017.Variation of arsenic valence and its effect on bacteria during biooxidation of refractory gold concentrate containing arsenic[J].Gold Science and Technology,25(4):106-112. |

| null | Zhong Shuiping,2011.Biological pre-oxidation of refractory gold ores containing high As [J].Nonferrous Metals Engineering & Research,32(2):16-18. |

| null | Zhou Yuan, Tian Shuguo, Liu Liang,et al,2009.Progress of arsenic removal pretreatment technology for high arsenic gold ores [J].Metal Mine,38(27):98-101. |

| null | 曹欣,雷力,王智伟,等,2021.川北高砷高碳微细粒难处理金矿石焙烧工艺研究[J].黄金,42(5):52-55. |

| null | 崔丙贵,康国爱,陈发上,等,2017.生物氧化预处理高砷金精矿试验研究及应用[J].黄金,38(8):56-58. |

| null | 崔日成,杨洪英,富瑶,等,2011.不同含砷类型金矿的细菌氧化—氰化浸出[J].中国有色金属学报,21(3):694-699. |

| null | 方兆珩,夏光祥,石伟,等,2001.高砷含锑难浸金精矿提金工艺的研究[J].黄金科学技术,9(3):28-35. |

| null | 柯家骏,2005.湿法冶金手册 [M].北京:冶金工业出版社. |

| null | 柯平超,刘志宏,刘智勇,等,2016.固砷矿物臭葱石组成与结构及其浸出稳定性研究现状[J].化工学报,67(11):4533-4540. |

| null | 雷占昌,虞洁,马红蕊,2014.难处理金矿预处理技术现状及进展[J].现代矿业,30(5):23-24,33. |

| null | 刘汉钊,1993.富砷碳超微细粒金矿提金工艺探讨[J].矿产综合利用,1(3):8-16. |

| null | 刘俊壮,黄万抚,2010.含高砷金矿浸金工艺研究现状[J].现代矿业,26(10):26-29. |

| null | 刘树根,田学达,2005.含砷固体废物的处理现状与展望[J].湿法冶金,23(4):183-186. |

| null | 孟宇群,王隆保,2001.低温低氧势焙烧预处理难浸金矿[J].有色金属,53(4):29-32,40. |

| null | 沈蔡龙,贾炎,陈彦臻,等,2022.化工技术在生物冶金过程强化中的研究进展[J].过程工程学报,22(10):1349-1359. |

| null | 舒波,周尚,张宝辉,等,2020.有色冶炼含砷污酸处置及固砷技术进展[J].矿产保护与利用,40(3):12-20. |

| null | 王金生,连海瑛,蹇令兰,2013.黄金冶炼焙烧烟气中砷的回收[J].黄金,34(7):65-68. |

| null | 王力军,罗远辉,高洪山,等,2005.难处理金矿二次包裹现象研究[J].稀有金属,29(4):424-428. |

| null | 王帅,李超,李宏煦,2014.难浸金矿预处理技术及其研究进展[J].黄金科学技术,22(4):129-134. |

| null | 吴浩,2021.含砷难浸金矿碱性加压自浸金机理及工艺研究[D].北京:北京科技大学. |

| null | 席欣月,崔毅琦,王玉波,等,2022.含砷硫化矿物对浸金影响的研究进展[J].化工矿物与加工,51(4):10-14,25. |

| null | 夏光祥,方兆珩,石伟,2001.难浸金矿的提金技术与展望[J].有色冶炼,30(4):31-34. |

| null | 夏光祥,石伟,涂桃枝,等,1996.氨浸法预处理含砷难浸金矿石的应用研究[J].黄金,17(10):28-34. |

| null | 熊民,史冠勇,田磊,等,2022.碳热焙烧还原砷酸钙制备金属砷[J].工程科学学报,44(5):886-893. |

| null | 张磊,郭学益,田庆华,等,2021.难处理金矿预处理方法研究进展及工业应用[J].黄金,42(6):60-68. |

| null | 张玉秀,郭德庚,李媛媛,等,2017.含砷难处理金精矿生物预氧化过程中砷价态的变化及其对细菌的影响[J].黄金科学技术,25(4):106-112. |

| null | 衷水平,2011.高砷难处理金矿生物搅拌预氧化工艺研究[J].有色冶金设计与研究,32(2):16-18. |

| null | 周源,田树国,刘亮,等,2009.高砷金矿脱砷预处理技术进展[J].金属矿山,38(27):98-101. |

/

| 〈 |

|

〉 |