地下矿的岩体是一个极为复杂的动态系统,其影响因素众多。地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] 。国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] 。

近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] 。上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法。云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价。因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法。

1 基础理论

1.1 CRITIC法

CRITIC法可通过分析各指标数据间的内在联系和离散性大小来计算各指标权重。其具体计算步骤主要有[21 ] :

(1)数据标准化。假设有n 个样本,每个样本有m 个指标值,由于各指标间的量纲有所差异,采用式(1)对原始数据进行标准化:

a i j = x i j - x j m i n x j m a x - x j m i n (1)

式中:a i j xij 为第i 个样本的第j 项指标值;x j m a x j 的最大值;x j m i n j 的最小值。

(2)计算标准差。将指标j 的指标向量记为X j σ j

(3)计算相关系数。计算指标b 与指标j 的相关系数r b j

(4)计算信息量。指标j 所拥有的信息量Cj 的计算公式为

C j = σ j ∑ b = 1 m 1 - r b j ( b = 1,2 , ⋯ , m ;

j = 1,2 , ⋯ , m ) (2)

ω j = C j / ∑ j = 1 m C j (3)

1.2 云模型(CW)

云模型[20 ] 是一种可对定性概念采用定量数值表达的数学模型,已被成功应用于岩爆预测[22 ] 和采矿区稳定性分析[23 ] 等领域。设Y 为一定量论域,C 为Y 上一定性概念,若论域中数值x 对C 的确定度y ( x ) ∈ [ 0,1 ] x 在论域Y 上的分布为云,称任何一组(x ,y )为一个云滴。云滴的确定度定量表示了模糊性,可用某一概率分布函数表示。

期望Ex 、熵En 和超熵He 为云模型的3个重要参数。其中,Ex 为分布函数的期望,可较好地反映云模型的定性特征;En 表示云滴离散性的大小;He 表示En 的熵值。

云发生器有正向云发生器和逆向云发生器2种。其中,由已知论域Y 中某一数值x 经云发生器生成定性概念C 的分布的发生器称为正向云发生器,反之称为逆向云发生器。

E n ' = N ( E n , H e 2 ) (4)

x = N ( E n , E n ' 2 ) (5)

y = e x p - ( x - E x ) 2 2 E n ' 2 (6)

(5)重复N 次流程(2)~(4),生成N 个云滴。云模型的3个重要参数的计算公式为

E x = C m i n + C m a x 2 E n = C m a x - C m i n 2.355 H e = k (7)

式中:C m a x C m i n k 一般取0.002。

2 模型验证

2.1 岩体质量评价指标选取

地下矿的岩体质量受多因素共同影响,本文参考文献[24 ,25 ,26 ]中岩体质量的评价标准,选取了岩石质量指标RQD(X 1 )、岩石单轴饱和抗压强度R W (X 2 )、岩体完整性系数K v(X 3 )、结构面强度系数K f (X 4 )和地下水渗水量ω (X 5 )共5个指标来评价地下矿岩体质量,如表1 所示。由表1 可知,该标准将岩体质量划分为Ⅰ级、Ⅱ级、Ⅲ级、Ⅳ级和Ⅴ级,其中Ⅰ级表示岩体质量最好,Ⅴ级表示岩体质量最差。

2.2 基于CRITIC的指标权重确定

岩体质量不同评价指标间具有模糊性和不确定性,若对各指标均采用相同权重计算,显然不合理,因此,本文采用CRITIC法计算各指标的客观权重。以文献[24 ]数据作为样本数据,如表2 所示。

采用第1.1小节中步骤(1)~(5)对表2 中20组样本数据进行计算,得到了岩体质量评价的5项评价指标(X 1 ,X 2 ,X 3 ,X 4 ,X 5 )的权重,分别为0.1558、0.1416、0.1574、0.1608和0.3844。

2.3 分级结果确定及模型检验

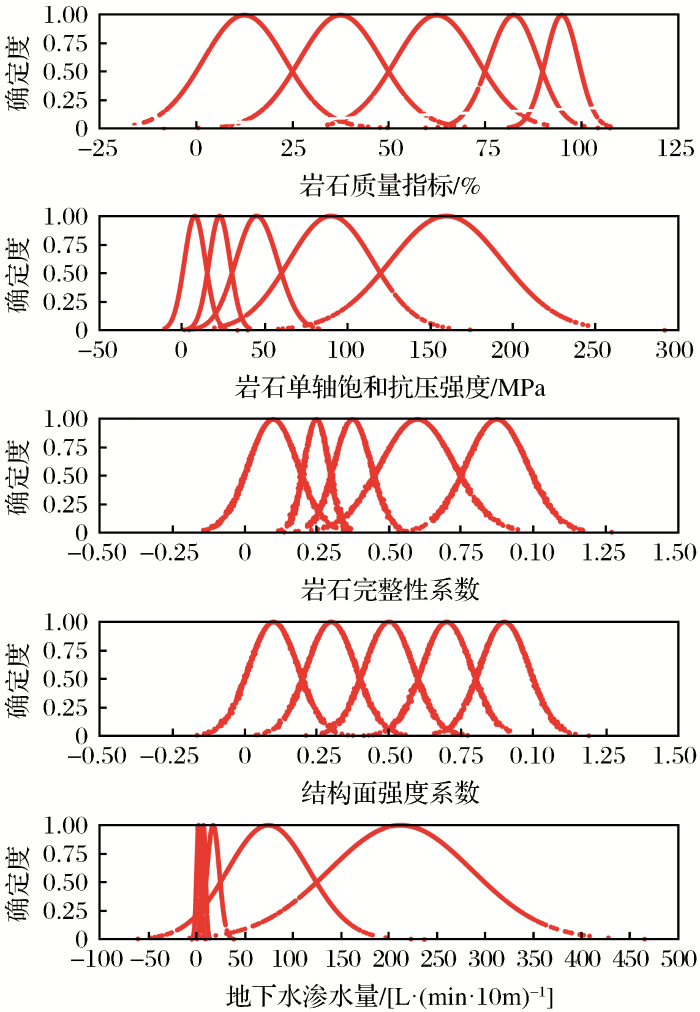

基于高斯正向云发生器的计算流程,采用式(3),(4),(5),(6),(7)对表1 中岩体质量评价标准生成云模型,指标j 隶属于等级c 的最大确定度取1,不同等级的边界处进行了模糊化处理,结果如图1 所示。

图1

图1

各指标隶属于不同岩体质量等级的云模型

Fig.1

Cloud model with different rock mass quality grades for each index

由云发生器的计算步骤可知,云模型的计算过程复杂,需多次计算生成相应云滴,设有n 个样本,每个样本有m 个评价指标,则样本i 的第j 个指标隶属于等级q 的确定度yijq 采用式(8)计算:

y i j q = ∑ s = 1 N y i j q s N ( i = 1,2 , ⋯ , n ; j = 1,2 , ⋯ , m ; q = 1,2 , ⋯ , 5 ; s = 1,2 , ⋯ , 1 000 ) (8)

式中:N 为云发生器运行次数,本文取N =1 000;y i j q s i 的第j 个指标隶属于等级q 的第s 次确定度。

Y i q = ∑ j = 1 m ( y i j q ω j ) ( i = 1,2 , ⋯ , n ; j = 1,2 , ⋯ , m ; q = 1,2 , ⋯ , 5 ) (9)

为验证本文CRITIC-CW方法的可靠性,选取了文献[21 ]中20组数据作为样本数据进行模型验证,采用第2.2小节中5项评价指标的权重,基于高斯正向云发生器算法,运用式(4),(5),(6),(7),(8),(9)对表2 中20组岩体质量评价样本数据进行计算,计算结果如表2 所示。由表2 可知,只有样本17的评价结果失误,其余样本的评价结果均与实测等级相吻合,说明本文方法具有较高的准确性和可靠性,可用于岩体质量评价。

3 工程应用实例

3.1 工程概况

三山岛金矿新立矿区是我国唯一在采的海下金矿,矿区地质条件和围岩质量变化较复杂,在生产过程中,常由于爆破振动、机械凿岩等活动发生局部浮石掉落、冒顶和塌方等灾害,严重威胁着矿山的生产安全。因此,亟需对该区域岩体进行详细地质调查,并进行岩体质量评价,从而为后续施工方式和支护工艺的选择提供依据。本文选取了新立矿区-200 m中段、-240 m中段和-320 m中段部分典型区域的岩体进行了地质调查,获得了各项评价指标数据,如表3 所示。

3.2 结果分析

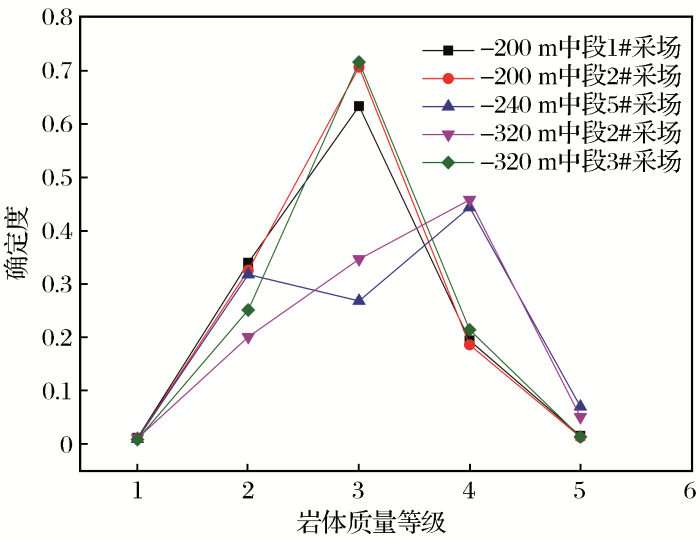

运用CRITIC-CW方法对表3 中各样本进行岩体质量评价,得到了各样本隶属于岩体质量等级Ⅰ~Ⅴ的确定度,如图2 所示。由图2 可知,各样本隶属于不同岩体质量等级的确定度曲线存在且只存在一个最大值,各样本确定度最大值对应岩体质量等级如表4 所示。由表4 可知,该矿区岩体质量主要为Ⅲ级和Ⅳ级,通过对比各样本5项指标值与岩体质量分级标准中不同等级5项指标的取值范围,可侧面验证表5中评价结果基本合理。该矿区围岩质量较差,不太稳固,在进行矿山工程建设中存在围岩冒落隐患,需对Ⅳ级围岩加强支护。经现场验证,对-240 m中段5#采场和-320 m中段2#采场及周围巷道采取了较-200 m中段1#采场周边巷道更小的锚杆支护间距,局部增加锚网支护后,该区域围岩冒落现象明显减少。

图2

图2

各样本隶属于不同岩体质量等级的确定度

Fig.2

Determination of different rock mass quality grades by different samples

4 结论

(1)基于CRITIC法对20组岩体质量评价样本数据进行分析计算,挖掘其内在联系和离散性,得到了评价岩体质量的岩石质量指标、岩石单轴饱和抗压强度、岩体完整性系数、结构面强度系数和地下水渗水量5项指标的权重值。

(2)运用CRITIC-CW法对20组岩体的质量评价样本数据进行评价,并与20组样本的实测岩体质量等级进行对比分析,结果表明CRITIC法只有一个误判,其余评价结果均正确,说明CRITIC-CW法具有较高的准确性和可靠性。

(3)将CRITIC-CW法应用于三山岛金矿新立矿区部分区域岩体质量评价,结果表明该区域岩体质量主要为Ⅲ级和Ⅳ级,岩体质量较差,对岩体质量为Ⅳ级的巷道及采场裸露围岩需加强支护。

(4)CRITIC-CW法在评价岩体质量过程中侧重于量化分析评价指标间的模糊性,但影响岩体质量的因素众多,选取不同评价指标评价结果可能会有所差异,下一步将在本文基础上探索更加科学合理的岩体质量评价指标的选取方法。

参考文献

View Option

[1]

文畅平 基于属性数学理论的岩体质量分级方法

[J].水力发电学报 ,2008 ,27 (3 ):75 -80 .

[本文引用: 1]

Wen Changping Classification of rock-mass stability based on attributive mathematical theory

[J].Journal of Hydroelectric Engineering ,2008 ,27 (3 ):75 -80 .

[本文引用: 1]

[2]

赵星光 ,蔡明 ,蔡美峰 剪胀对地下工程岩体位移的影响——以加拿大 Donkin-Morien隧道为例

[J].岩石力学与工程学报 ,2010 ,29 (11 ):2186 -2195 .

[本文引用: 1]

Zhao Xingguang Cai Ming Cai Meifeng Influence of dilation on rock mass displacement around underground excavations:A case study of Donkin-Morien tunnel in Canada

[J].Chinese Journal of Rock Mechanics and Engineering ,2010 ,29 (11 ):2185 -2195 .

[本文引用: 1]

[3]

Cai M Kaiser P Visualization of rock mass classification systems

[J].Geotechnical and Geological Engineering ,2006 ,24 (4 ):1089 -1102 .

[本文引用: 1]

[4]

Barton N Lien R Lunde J Engineering classification of rock masses for the design of tunnel support

[J].Rock Mechanics ,1974 ,6 (4 ):189 -236 .

[本文引用: 1]

[5]

Bieniawski Z T Engineering classification of jointed rock masses

[J].Transactions of South African Institution of Civil Engineers ,1973 ,15 (12 ):335 -344 .

[本文引用: 1]

[6]

邬爱清 ,汪斌 基于岩体质量指标BQ的岩质边坡工程岩体分级方法

[J].岩石力学与工程学报 ,2014 ,33 (4 ):699 -706 .

[本文引用: 1]

Wu Aiqing Wang Bin Engineering rock mass classification method based on rock mass quality index BQ for rock slope

[J].Chinese Journal of Rock Mechanics and Engineering ,2014 ,33 (4 ):699 -706 .

[本文引用: 1]

[7]

陈昌彦 ,王贵荣 各类岩体质量评价方法的相关性探讨

[J].岩石力学与工程学报 ,2002 ,21 (12 ):1894 -1900 .

[本文引用: 1]

Chen Changyan Wang Guirong Discussion on the interrelation of various rock mass quality classification systems at home and abroad

[J].Chinese Journal of Rock Mechanics and Engineering ,2002 ,21 (12 ):1894 -1900 .

[本文引用: 1]

[8]

许梦国 ,王明旭 ,王平 ,等 程潮铁矿岩体分级及其在巷道支护中的应用

[J].黄金 ,2013 ,34 (4 ):41 -45 .

[本文引用: 1]

Xu Mengguo Wang Mingxu Wang Ping et al Rock mass classification and its application in tunnel support in Chengchao iron mine

[J].Gold ,2013 ,34 (4 ):41 -45 .

[本文引用: 1]

[9]

穆锡川 ,李景波 ,刘杰 ,等 大柳行金矿床节理裂隙调查与岩体质量评价

[J].黄金 ,2017 ,38 (5 ):43 -46 ,53 .

[本文引用: 1]

Mu Xichuan Li Jingbo Liu Jie et al Investigation into the joint fissures and evaluation of rock mass quality in Daliuxing gold deposit

[J].Gold ,2017 ,38 (5 ):43 -46 ,53 .

[本文引用: 1]

[10]

Shen Y J Yan R X Yang G S et al Comparisons of evaluation factors and application effects of the new[BQ]GSI system with international rock mass classification systems

[J].Geotechnical and Geological Engineering ,2017 ,35 (6 ):2523 -2548 .

[本文引用: 1]

[11]

刘强 ,李夕兵 ,梁伟章 岩体质量分类的PCA-RF模型及应用

[J].黄金科学技术 ,2018 ,26 (1 ):49 -55 .

[本文引用: 1]

Liu Qiang Li Xibing Liang Weizhang PCA-RF model for the classification of rock mass quality and its application

[J].Gold Science and Technology ,2018 ,26 (1 ):49 -55 .

[本文引用: 1]

[12]

张海磊 ,严文炳 ,郭生茂 ,等 基于ELM模型的岩体质量分级及应用

[J].黄金 ,2018 ,39 (12 ):32 -34 .

[本文引用: 1]

Zhang Hailei Yan Wenbing Guo Shengmao et al Classification of rock mass quality in a mine based on ELM model and its application

[J].Gold ,2018 ,39 (12 ):32 -34 .

[本文引用: 1]

[13]

邱道宏 ,陈剑平 ,阙金声 ,等 基于粗糙集和人工神经网络的洞室岩体质量评价

[J].吉林大学学报(地球科学版) ,2008 ,38 (1 ):86 -91 .

[本文引用: 1]

Qiu Daohong Chen Jianping Que Jinsheng et al Evaluation of tunnel rock quality with routh sets theory and artificial neural networks

[J].Journal of Jilin University(Earth Science) ,2008 ,38 (1 ):86 -91 .

[本文引用: 1]

[14]

胡建华 ,艾自华 基于最优组合赋权的地下矿山岩体质量可拓评价模型

[J].黄金科学技术 ,2017 ,25 (4 ):39 -45 .

[本文引用: 1]

Hu Jianhua Ai Zihua Extension evaluation model of rock mass quality for underground mine based on optimal combination weighting

[J].Gold Science and Technology ,2017 ,25 (4 ):39 -45 .

[本文引用: 1]

[15]

吴肖坤 ,刘敦文 ,江帆 ,等 基于特征值域的可拓学理论的工程岩体质量评价

[J].黄金科学技术 ,2015 ,23 (2 ):68 -75 .

[本文引用: 1]

Wu Xiaokun Liu Dunwen Jiang Fan et al Extension theory of engineering rock mass quality evaluation based on the feature range

[J].Gold Science and Technology ,2015 ,23 (2 ):68 -75 .

[本文引用: 1]

[16]

宫凤强 ,李夕兵 距离判别分析法在岩体质量等级分类中的应用

[J].岩石力学与工程学报 ,2007 ,26 (1 ):190 -194 .

[本文引用: 1]

Gong Fengqiang Li Xibing Application of distance discriminant analysis method to classification of engineering quality of rock masses

[J].Chinese Journal of Rock Mechanics and Engineering ,2007 ,26 (1 ):190 -194 .

[本文引用: 1]

[17]

梁桂兰 ,徐卫亚 ,谈小龙 基于熵权的可拓理论在岩体质量评价中的应用

[J].岩土力学 ,2010 ,31 (2 ):535 -540 .

[本文引用: 1]

Liang Guilan Xu Weiya Tan Xiaolong Application of extension theory based on entropy weight to rock quality evaluation

[J].Rock and Soil Mechanics ,2010 ,31 (2 ):535 -540 .

[本文引用: 1]

[18]

陈赞成 ,余斌 ,胡建军 ,等 呼的合铜矿工程地质调查与岩体质量评价

[J].黄金 ,2013 ,34 (6 ):35 -39 .

[本文引用: 1]

Chen Zancheng Yu Bin Hu Jianjun et al Engineering geological investigation and rock mass quality evaluation of Hudehe copper mine

[J].Gold ,2013 ,34 (6 ):35 -39 .

[本文引用: 1]

[19]

McEwen T Kapyaho A Hella P et al Rock suitability classification RSC 2012

[R].Helsinki :Posiva Oy ,2012 .

[本文引用: 1]

[20]

李德毅 ,杜鹢 不确定性人工智能 [M].北京 :国防工业出版社 ,2005 .

[本文引用: 2]

Li Deyi Du Yu Artificial Intelligence with Uncertainty [M].Beijing :National Defense Industry Press ,2005 .

[本文引用: 2]

[21]

Diakoulaki D Mavrotas G Papayannakis L Determining objective weights in multiple criteria problems:The CRITIC method

[J].Computers and Operations Research ,1995 ,22 (7 ):763 -770 .

[本文引用: 3]

[22]

李绍红 ,王少阳 ,朱建东 ,等 基于权重融合和云模型的岩爆倾向性预测研究

[J].岩土工程学报 ,2018 ,40 (6 ):1075 -1083 .

[本文引用: 1]

Li Shaohong Wang Shaoyang Zhu Jiandong et al Prediction of rock burst tendency based on weighted fusion and improved cloud model

[J].Chinese Journal of Geotechnical Engineering ,2018 ,40 (6 ):1075 -1083 .

[本文引用: 1]

[23]

赵国彦 ,梁伟章 ,洪昌寿 采空区稳定性的改进云模型二维评判

[J].中国安全科学学报 ,2015 ,25 (10 ):102 -108 .

[本文引用: 1]

Zhao Guoyan Liang Weizhang Hong Changshou Improved cloud model for two dimensional stability evaluation of goaf

[J].China Safety Science Journal ,2015 ,25 (10 ):102 -108 .

[本文引用: 1]

[24]

胡建华 ,尚俊龙 ,雷涛 基于RS-TOPSIS法的地下工程岩体质量评价

[J].中南大学学报(自然科学版) ,2012 ,43 (11 ):4412 -4419 .

[本文引用: 4]

Hu Jianhua Shang Junlong Lei Tao Rock mass quality evaluation of underground engineering based on RS-TOPSIS method

[J].Journal of Central South University(Science and Technology) ,2012 ,43 (11 ):4412 -4419 .

[本文引用: 4]

[25]

蔡广奎 围岩稳定性分类的BP 网络模型的研究

[D].南京 :河海大学 ,2001 .

[本文引用: 3]

Cai Guangkui Study of the BP Neural Network on the Stability Classification of Surrounding Rocks

[D].Nanjing :Hehai University ,2001 .

[本文引用: 3]

[26]

杨朝晖 ,刘浩吾 地下工程围岩稳定性分类的人工神经网络模型

[J].四川联合大学学报(工程科学版) ,1999 ,3 (4 ):66 -72 .

[本文引用: 3]

Yang Chaohui Liu Haowu Artificial neural network model for the stability classification of adjoining rock of underground construction

[J].Journal of Sichuan Union University(Engineering Science Edition) ,1999 ,3 (4 ):66 -72 .

[本文引用: 3]

基于属性数学理论的岩体质量分级方法

1

2008

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

基于属性数学理论的岩体质量分级方法

1

2008

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

剪胀对地下工程岩体位移的影响——以加拿大 Donkin-Morien隧道为例

1

2010

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

剪胀对地下工程岩体位移的影响——以加拿大 Donkin-Morien隧道为例

1

2010

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

Visualization of rock mass classification systems

1

2006

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

Engineering classification of rock masses for the design of tunnel support

1

1974

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

Engineering classification of jointed rock masses

1

1973

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

基于岩体质量指标BQ的岩质边坡工程岩体分级方法

1

2014

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

基于岩体质量指标BQ的岩质边坡工程岩体分级方法

1

2014

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

各类岩体质量评价方法的相关性探讨

1

2002

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

各类岩体质量评价方法的相关性探讨

1

2002

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

程潮铁矿岩体分级及其在巷道支护中的应用

1

2013

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

程潮铁矿岩体分级及其在巷道支护中的应用

1

2013

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

大柳行金矿床节理裂隙调查与岩体质量评价

1

2017

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

大柳行金矿床节理裂隙调查与岩体质量评价

1

2017

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

Comparisons of evaluation factors and application effects of the new[BQ]GSI system with international rock mass classification systems

1

2017

... 地下矿的岩体是一个极为复杂的动态系统,其影响因素众多.地下矿岩体质量评价不仅是了解地下矿岩体特性的重要手段,更是地下矿设计、施工及灾害防治等工作的重要基础数据,因此研究地下矿岩体质量评价具有重要意义[1 ,2 ,3 ] .国内外关于岩体质量评价的研究众多,早期的岩体质量评价方法主要有RQD法、Q法[4 ] 、RMR法[5 ] 和BQ法等[6 ,7 ,8 ,9 ,10 ] . ...

岩体质量分类的PCA-RF模型及应用

1

2018

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

岩体质量分类的PCA-RF模型及应用

1

2018

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于ELM模型的岩体质量分级及应用

1

2018

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于ELM模型的岩体质量分级及应用

1

2018

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于粗糙集和人工神经网络的洞室岩体质量评价

1

2008

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于粗糙集和人工神经网络的洞室岩体质量评价

1

2008

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于最优组合赋权的地下矿山岩体质量可拓评价模型

1

2017

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于最优组合赋权的地下矿山岩体质量可拓评价模型

1

2017

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于特征值域的可拓学理论的工程岩体质量评价

1

2015

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于特征值域的可拓学理论的工程岩体质量评价

1

2015

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

距离判别分析法在岩体质量等级分类中的应用

1

2007

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

距离判别分析法在岩体质量等级分类中的应用

1

2007

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于熵权的可拓理论在岩体质量评价中的应用

1

2010

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

基于熵权的可拓理论在岩体质量评价中的应用

1

2010

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

呼的合铜矿工程地质调查与岩体质量评价

1

2013

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

呼的合铜矿工程地质调查与岩体质量评价

1

2013

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

Rock suitability classification RSC 2012

1

2012

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

2

2005

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

... 云模型[20 ] 是一种可对定性概念采用定量数值表达的数学模型,已被成功应用于岩爆预测[22 ] 和采矿区稳定性分析[23 ] 等领域.设Y 为一定量论域,C 为Y 上一定性概念,若论域中数值x 对C 的确定度y ( x ) ∈ [ 0,1 ] x 在论域Y 上的分布为云,称任何一组(x ,y )为一个云滴.云滴的确定度定量表示了模糊性,可用某一概率分布函数表示. ...

2

2005

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

... 云模型[20 ] 是一种可对定性概念采用定量数值表达的数学模型,已被成功应用于岩爆预测[22 ] 和采矿区稳定性分析[23 ] 等领域.设Y 为一定量论域,C 为Y 上一定性概念,若论域中数值x 对C 的确定度y ( x ) ∈ [ 0,1 ] x 在论域Y 上的分布为云,称任何一组(x ,y )为一个云滴.云滴的确定度定量表示了模糊性,可用某一概率分布函数表示. ...

Determining objective weights in multiple criteria problems:The CRITIC method

3

1995

... 近年来,随着数学及计算机科学的发展,大量新理论及数学方法被应用于岩体质量评价中,这些方法大致可划分为3类:(1)基于智能算法(随机森林、神经网络和极限学习机等)进行岩体质量评价,其特点是通过训练样本数据,拟合得到一种样本指标与岩体质量等级间的非线性函数[11 ,12 ,13 ] ;(2)基于距离判别(可拓理论和马氏距离等)的评价方法,其特点是通过构建样本与评价标准的上下区间的距离函数进行岩体质量评价[14 ,15 ,16 ,17 ] ;(3)基于修正系数的评价方法,其特点是对早期的岩体质量评价公式添加修正系数,使评价结果具有更好的适应性和准确率[18 ,19 ] .上述研究在岩体质量评价领域均取得了显著成效,但岩体质量评价的模糊性和不确定性较强,目前尚无统一的评价方法.云模型理论[20 ] 可定量分析问题的模糊性,非常适用于岩体质量评价多指标间的随机性和模糊性评价.因此,本文引入云模型理论,并采用CRITIC法[21 ] 确定评价指标的权重,以期丰富岩体质量评价相关理论与方法. ...

... CRITIC法可通过分析各指标数据间的内在联系和离散性大小来计算各指标权重.其具体计算步骤主要有[21 ] : ...

... 为验证本文CRITIC-CW方法的可靠性,选取了文献[21 ]中20组数据作为样本数据进行模型验证,采用第2.2小节中5项评价指标的权重,基于高斯正向云发生器算法,运用式(4) ,(5) ,(6) ,(7) ,(8) ,(9) 对表2 中20组岩体质量评价样本数据进行计算,计算结果如表2 所示.由表2 可知,只有样本17的评价结果失误,其余样本的评价结果均与实测等级相吻合,说明本文方法具有较高的准确性和可靠性,可用于岩体质量评价. ...

基于权重融合和云模型的岩爆倾向性预测研究

1

2018

... 云模型[20 ] 是一种可对定性概念采用定量数值表达的数学模型,已被成功应用于岩爆预测[22 ] 和采矿区稳定性分析[23 ] 等领域.设Y 为一定量论域,C 为Y 上一定性概念,若论域中数值x 对C 的确定度y ( x ) ∈ [ 0,1 ] x 在论域Y 上的分布为云,称任何一组(x ,y )为一个云滴.云滴的确定度定量表示了模糊性,可用某一概率分布函数表示. ...

基于权重融合和云模型的岩爆倾向性预测研究

1

2018

... 云模型[20 ] 是一种可对定性概念采用定量数值表达的数学模型,已被成功应用于岩爆预测[22 ] 和采矿区稳定性分析[23 ] 等领域.设Y 为一定量论域,C 为Y 上一定性概念,若论域中数值x 对C 的确定度y ( x ) ∈ [ 0,1 ] x 在论域Y 上的分布为云,称任何一组(x ,y )为一个云滴.云滴的确定度定量表示了模糊性,可用某一概率分布函数表示. ...

采空区稳定性的改进云模型二维评判

1

2015

... 云模型[20 ] 是一种可对定性概念采用定量数值表达的数学模型,已被成功应用于岩爆预测[22 ] 和采矿区稳定性分析[23 ] 等领域.设Y 为一定量论域,C 为Y 上一定性概念,若论域中数值x 对C 的确定度y ( x ) ∈ [ 0,1 ] x 在论域Y 上的分布为云,称任何一组(x ,y )为一个云滴.云滴的确定度定量表示了模糊性,可用某一概率分布函数表示. ...

采空区稳定性的改进云模型二维评判

1

2015

... 云模型[20 ] 是一种可对定性概念采用定量数值表达的数学模型,已被成功应用于岩爆预测[22 ] 和采矿区稳定性分析[23 ] 等领域.设Y 为一定量论域,C 为Y 上一定性概念,若论域中数值x 对C 的确定度y ( x ) ∈ [ 0,1 ] x 在论域Y 上的分布为云,称任何一组(x ,y )为一个云滴.云滴的确定度定量表示了模糊性,可用某一概率分布函数表示. ...

基于RS-TOPSIS法的地下工程岩体质量评价

4

2012

... 地下矿的岩体质量受多因素共同影响,本文参考文献[24 ,25 ,26 ]中岩体质量的评价标准,选取了岩石质量指标RQD(X 1 )、岩石单轴饱和抗压强度R W (X 2 )、岩体完整性系数K v(X 3 )、结构面强度系数K f (X 4 )和地下水渗水量ω (X 5 )共5个指标来评价地下矿岩体质量,如表1 所示.由表1 可知,该标准将岩体质量划分为Ⅰ级、Ⅱ级、Ⅲ级、Ⅳ级和Ⅴ级,其中Ⅰ级表示岩体质量最好,Ⅴ级表示岩体质量最差. ...

... 岩体质量分级标准[24 ,25 ,26 ] ...

... Standards for rock mass quality classification[24 ,25 ,26 ] ...

... 岩体质量不同评价指标间具有模糊性和不确定性,若对各指标均采用相同权重计算,显然不合理,因此,本文采用CRITIC法计算各指标的客观权重.以文献[24 ]数据作为样本数据,如表2 所示. ...

基于RS-TOPSIS法的地下工程岩体质量评价

4

2012

... 地下矿的岩体质量受多因素共同影响,本文参考文献[24 ,25 ,26 ]中岩体质量的评价标准,选取了岩石质量指标RQD(X 1 )、岩石单轴饱和抗压强度R W (X 2 )、岩体完整性系数K v(X 3 )、结构面强度系数K f (X 4 )和地下水渗水量ω (X 5 )共5个指标来评价地下矿岩体质量,如表1 所示.由表1 可知,该标准将岩体质量划分为Ⅰ级、Ⅱ级、Ⅲ级、Ⅳ级和Ⅴ级,其中Ⅰ级表示岩体质量最好,Ⅴ级表示岩体质量最差. ...

... 岩体质量分级标准[24 ,25 ,26 ] ...

... Standards for rock mass quality classification[24 ,25 ,26 ] ...

... 岩体质量不同评价指标间具有模糊性和不确定性,若对各指标均采用相同权重计算,显然不合理,因此,本文采用CRITIC法计算各指标的客观权重.以文献[24 ]数据作为样本数据,如表2 所示. ...

围岩稳定性分类的BP 网络模型的研究

3

2001

... 地下矿的岩体质量受多因素共同影响,本文参考文献[24 ,25 ,26 ]中岩体质量的评价标准,选取了岩石质量指标RQD(X 1 )、岩石单轴饱和抗压强度R W (X 2 )、岩体完整性系数K v(X 3 )、结构面强度系数K f (X 4 )和地下水渗水量ω (X 5 )共5个指标来评价地下矿岩体质量,如表1 所示.由表1 可知,该标准将岩体质量划分为Ⅰ级、Ⅱ级、Ⅲ级、Ⅳ级和Ⅴ级,其中Ⅰ级表示岩体质量最好,Ⅴ级表示岩体质量最差. ...

... 岩体质量分级标准[24 ,25 ,26 ] ...

... Standards for rock mass quality classification[24 ,25 ,26 ] ...

围岩稳定性分类的BP 网络模型的研究

3

2001

... 地下矿的岩体质量受多因素共同影响,本文参考文献[24 ,25 ,26 ]中岩体质量的评价标准,选取了岩石质量指标RQD(X 1 )、岩石单轴饱和抗压强度R W (X 2 )、岩体完整性系数K v(X 3 )、结构面强度系数K f (X 4 )和地下水渗水量ω (X 5 )共5个指标来评价地下矿岩体质量,如表1 所示.由表1 可知,该标准将岩体质量划分为Ⅰ级、Ⅱ级、Ⅲ级、Ⅳ级和Ⅴ级,其中Ⅰ级表示岩体质量最好,Ⅴ级表示岩体质量最差. ...

... 岩体质量分级标准[24 ,25 ,26 ] ...

... Standards for rock mass quality classification[24 ,25 ,26 ] ...

地下工程围岩稳定性分类的人工神经网络模型

3

1999

... 地下矿的岩体质量受多因素共同影响,本文参考文献[24 ,25 ,26 ]中岩体质量的评价标准,选取了岩石质量指标RQD(X 1 )、岩石单轴饱和抗压强度R W (X 2 )、岩体完整性系数K v(X 3 )、结构面强度系数K f (X 4 )和地下水渗水量ω (X 5 )共5个指标来评价地下矿岩体质量,如表1 所示.由表1 可知,该标准将岩体质量划分为Ⅰ级、Ⅱ级、Ⅲ级、Ⅳ级和Ⅴ级,其中Ⅰ级表示岩体质量最好,Ⅴ级表示岩体质量最差. ...

... 岩体质量分级标准[24 ,25 ,26 ] ...

... Standards for rock mass quality classification[24 ,25 ,26 ] ...

地下工程围岩稳定性分类的人工神经网络模型

3

1999

... 地下矿的岩体质量受多因素共同影响,本文参考文献[24 ,25 ,26 ]中岩体质量的评价标准,选取了岩石质量指标RQD(X 1 )、岩石单轴饱和抗压强度R W (X 2 )、岩体完整性系数K v(X 3 )、结构面强度系数K f (X 4 )和地下水渗水量ω (X 5 )共5个指标来评价地下矿岩体质量,如表1 所示.由表1 可知,该标准将岩体质量划分为Ⅰ级、Ⅱ级、Ⅲ级、Ⅳ级和Ⅴ级,其中Ⅰ级表示岩体质量最好,Ⅴ级表示岩体质量最差. ...

... 岩体质量分级标准[24 ,25 ,26 ] ...

... Standards for rock mass quality classification[24 ,25 ,26 ] ...

甘公网安备 62010202000672号

甘公网安备 62010202000672号