在金属矿山地下开采过程中,穿孔爆破作业是其重要环节(袁节平等,2008;王辉林等,2012;程兵等,2023)。中深孔爆破技术被广泛应用于地下矿山开采,合理设计其装药结构能够极大地提高矿山生产效率,并有效保障矿山爆破作业质量及生产安全(杨恒涛,2017;王成龙等,2021;汪洋等,2022;骆浩浩等,2023;梁瑞等,2024)。目前扇形中深孔爆破设计工作存在大量人工重复操作。在装药设计过程中,需要根据炮孔分布情况、爆破参数和地质条件变化反复调整(赵艳伟等,2014;王平等,2015;刘猛,2017;周源,2019)。大量重复性装药设计计算工作费时费力,且在设计过程中,人机交互式调整装药仅能满足基本的爆破装药设计参数要求,主观随意性较大。

鉴于此,国内外学者对地下矿扇形中深孔装药设计方法进行了广泛而深入的研究。在经验公式优化领域,学者们深入探讨了地下采场环形爆破载荷的间距问题,通过优化钻孔和爆破参数,为地下矿山的爆破作业提供科学依据(Himanshu et al.,2021)。在CAD辅助工具应用方面,部分学者利用Visual Lisp等工具对CAD软件进行二次功能开发扩展,实现了扇形中深孔装药设计的自动化和高效化(周科平等,2017;刘益超等,2021)。在数值模拟分析方面,结合现场爆破试验和LS-DYN等数值模拟软件,对扇形中深孔爆破参数进行设计和优化,有效提升了爆破作业的安全性(Gao et al.,2023)。此外,在智能算法的探索中,利用改进极限学习机(ELM)和BP神经网络等算法,构建爆破设计模型,实现了爆破参数的智能化设定和装药优化调整(张耿城等,2021)。

综上所述,人机交互式设计、计算机模拟计算、参数自动化校准和成果优选等技术在爆破设计中展现出巨大的应用潜力和价值。然而,这些技术过于单一,并未体现系统工程学中的整体优化思想。鉴于此,本文将系统工程学中的最优化方法与爆破设计工程应用紧密结合,通过引入系统工程学的理论框架,深入探索并构建地下矿扇形中深孔装药参数化设计方法,以填补该研究领域的空白。

1 总体架构及思路

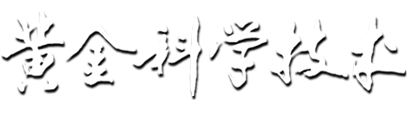

为进行地下矿扇形中深孔参数化装药设计,通过构建扇形中深孔装药数学模型,当模型接收到装药设计参数后,自动调整设计目标及约束条件,并重新求解获得最优设计成果。参数化装药设计方法总体流程如图1所示。

图1

图1

地下矿扇形中深孔装药设计方法总体流程

Fig.1

Overall flowchart of the charge design methodology for fan-shaped medium-deep hole in underground mines

1.1 设置扇形中深孔爆破装药参数

依据采场地质岩性、构造情况等工程条件,设置合理的扇形中深孔爆破装药参数。具体参数包括:最小填塞长度、装药影响半径、排间距、爆破范围面积、装药线密度、孔径、炸药单耗和离散化网格数量。

1.2 爆破范围提取与离散化

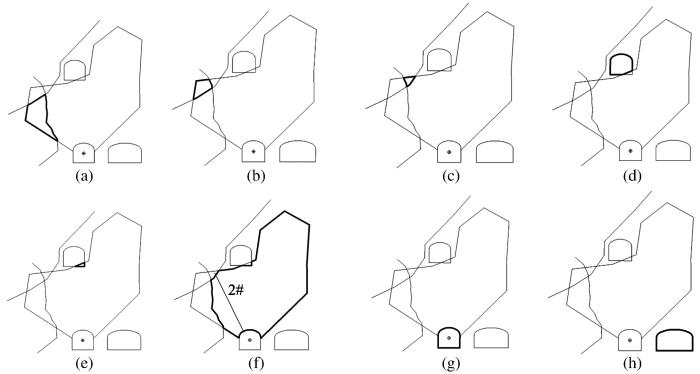

首先,根据矿岩分界面、采空区边界、爆破边界、巷道边界和机芯点位置的空间分布情况,提取所有矿岩分界面、采空区边界、爆破边界和巷道边界构成的最小闭环(夏红兵等,2008)。

然后,对任意一个炮孔,当该炮孔与矿岩分界面、采空区边界、爆破边界、巷道边界的交点仅有1个时,选择该炮孔的中点所在的最小闭环为爆破范围;当该炮孔与矿岩分界面、采空区边界、爆破边界、巷道边界的交点大于1个时,选择该炮孔的起点与下一个交点的中点所在的最小闭环为爆破范围。

1.3 装药参数化设计数学模型构建

基于参数化设计思想构建起地下矿扇形中深孔参数化装药设计数学模型。将扇形中深孔装药设计作业参数化,输入装药参数条件。经计算机计算输出装药设计结果,实现装药设计过程自动化。模型包括:参数、集合、索引、决策变量、目标函数和约束条件等。

1.4 装药参数化设计数学模型解算

以VC++为开发工具,通过运筹学方法解算该地下矿扇形中深孔参数化装药设计数学模型。通过模型解算结果确定最优扇形中深孔参数化装药设计方案。

2 地下矿扇形中深孔参数化装药设计数学模型构建

2.1 模型构建

基于参数化设计思想构建了地下矿扇形中深孔参数化装药设计数学模型。数学模型参数包括:离散化网格单元(

集合包括:爆破单位内离散化网格集合(A)、担负矿量关系集合(

集合的索引包括:离散化网格索引(i、k);炮孔的索引(j),装药结构方案索引(p)。

决策变量包括:

目标函数:Max

约束包括:

决策变量逻辑性约束:

炮孔j有且仅有一个装药结构方案为最终装药结构,表示为

装药与担负矿量关系约束:

其中,

炮孔间装药结构互斥性约束:

总装药量与炸药单耗匹配约束:

2.2 模型分析

基于参数化设计思想构建了地下矿扇形中深孔参数化装药设计数学模型。模型的目标是确保在各项约束条件下装药结构的影响范围最大。

模型包括多个约束条件。其中,式(3)~

3 研发与应用

3.1 研发背景

某地下矿山东采区100中段130分段矿块顶板岩性为矽卡岩和灰岩,矿块底板岩性为矽卡岩和砂岩。岩性完整性一般,底板岩性质量高于顶板。矿块内存在局部断层裂隙,包含滴水和断层填充物。受断层破坏的影响,断层附近岩性较为破碎。矿块地质储量为18.26万t,矿石品位TFe为43.22%,MFe为38.01%。

该采场采矿方法为分段凿岩阶段落矿空场采矿法。设计在115 m分段布置底部结构,各分段爆下矿石在底部结构出矿。每隔2 m设计一炮排排位,共计 28排。按照目前CAD手工装药设计模式,时间在4 h以上,作业效率低,炮孔装药过程繁琐。

3.2 工程应用

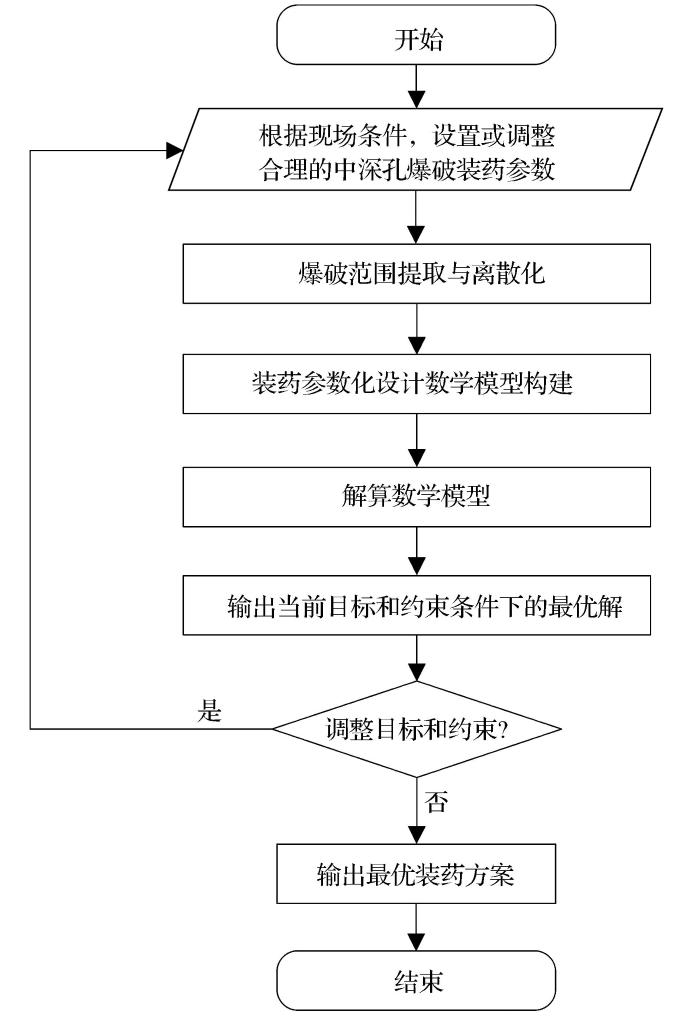

图2

图2

东采区100中段地质及井下开拓三维模型

Fig.2

3D model of geology and underground development in 100 middle section of east mining area

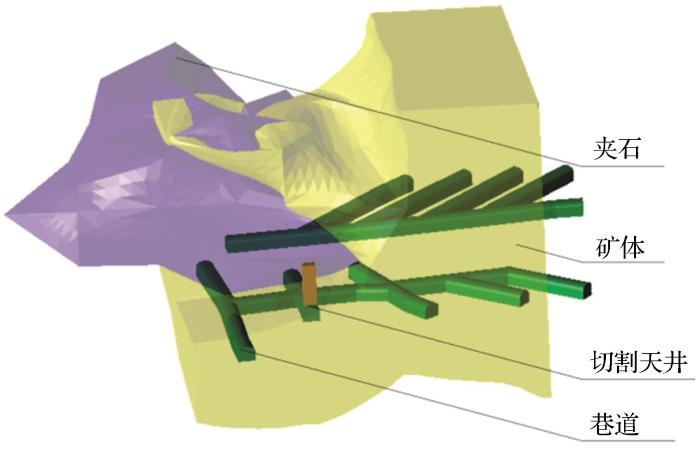

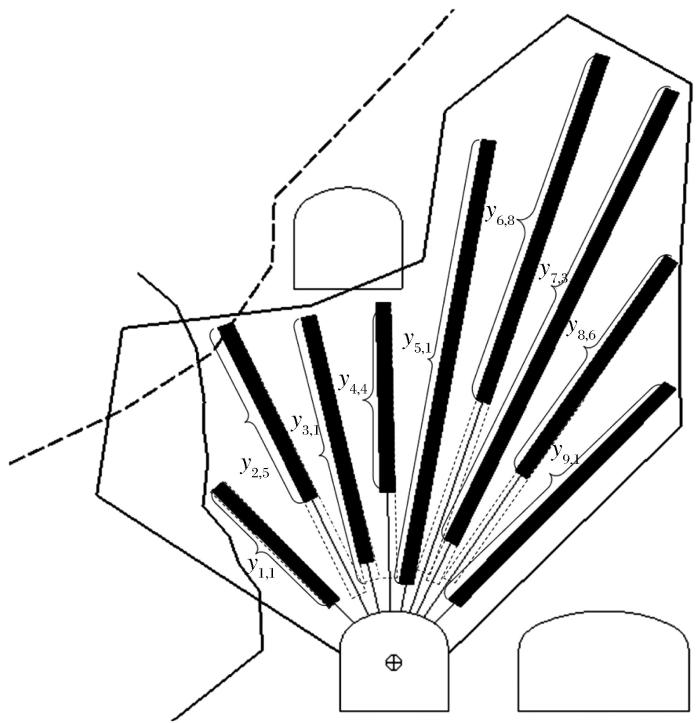

图3

图3

某地下矿山扇形中深孔爆破布孔设计成果

Fig.3

Design results of fan-shaped medium-deep holes blasting hole arrangement in an underground mine

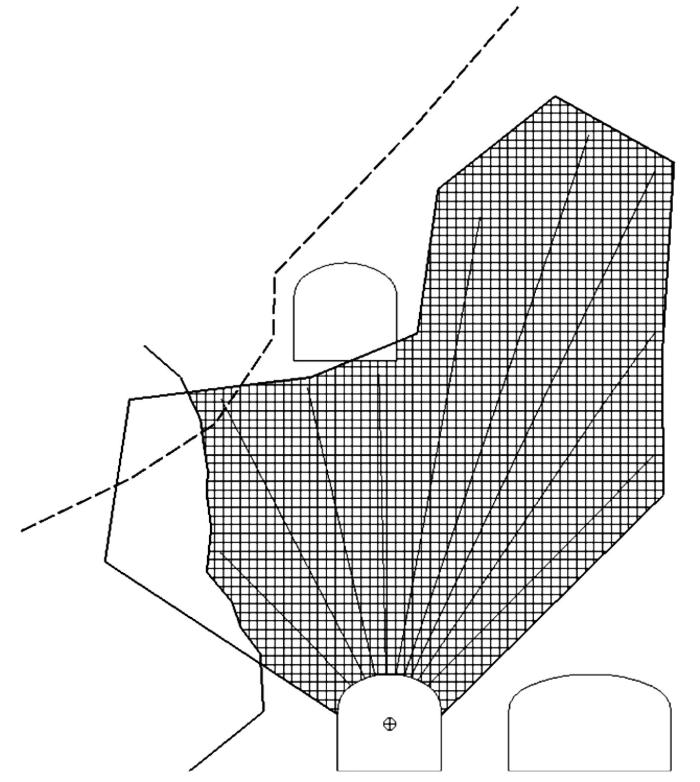

图4

图5

图6

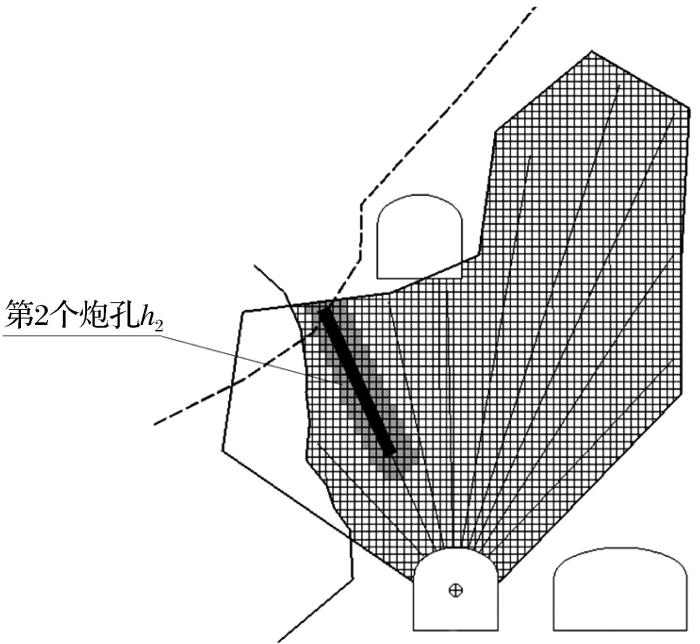

图6

装药结构与担负矿量关系

Fig.6

Relationship between the charge structure and the quantity of ore carried

建立地下矿山炮孔装药结构优化设计数学模型并求解。通过现场爆破试验及装药设计精度要求,确定此次爆破范围装药参数包括:最小填塞长度为1.0 m,装药影响半径为1.0 m,排间距为2.0 m,爆破范围面积为270.61 m2,装药线密度为4.8 kg/m,孔径为80 mm,炸药单耗为0.86 kg/m3,离散化网格尺寸为0.1 m×0.1 m。将上述参数代入第2.1小节模型中,得到本次参数化装药的数学模型。

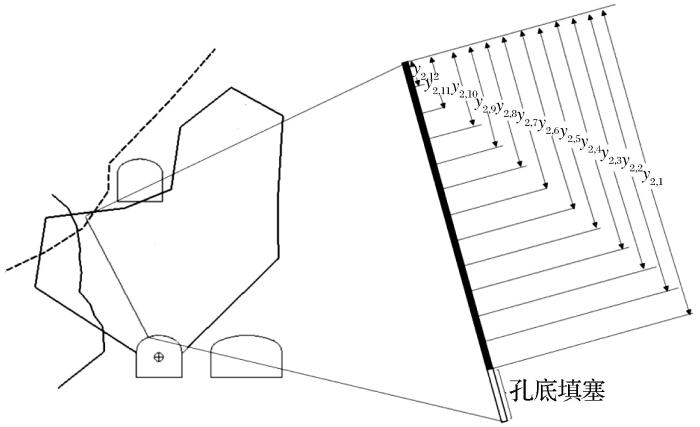

图7

图7

装药设计决策变量构建示意图

construction for charge design

Fig.7

Schematic diagram of decision variables

结合式(1)~

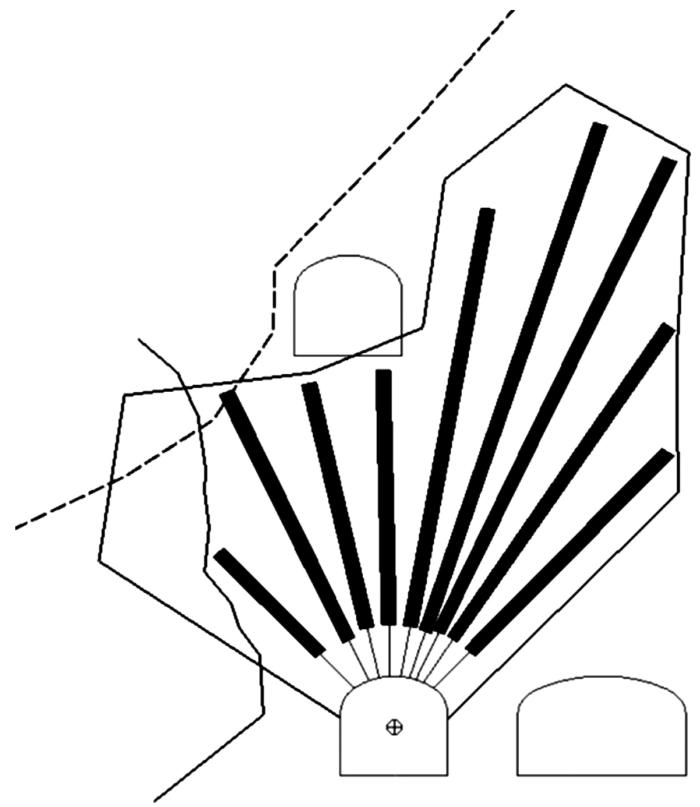

图8

图8

扇形中深孔最终爆破装药求解结果

Fig.8

Solution results of final blasting charge of fan-shaped medium-deep holes

利用CAD人机交互设计出的爆破装药结构如图9所示。

图9

表1 2种方式装药设计结果对比

Table 1

| 炮孔编号 | 本文方法 | 人机交互式方法 | |||

|---|---|---|---|---|---|

| 装药长度/m | 填塞长度/m | 装药长度/m | 填塞长度/m | ||

| 1# | 5.71 | 1.00 | 4.91 | 1.6 | |

| 2# | 7.48 | 3.95 | 9.63 | 1.6 | |

| 3# | 8.98 | 1.74 | 8.92 | 1.6 | |

| 4# | 6.68 | 4.14 | 9.02 | 1.6 | |

| 5# | 15.86 | 1.00 | 15.06 | 1.6 | |

| 6# | 13.44 | 7.32 | 18.96 | 1.6 | |

| 7# | 18.25 | 2.42 | 18.87 | 1.6 | |

| 8# | 10.4 | 4.89 | 13.49 | 1.6 | |

| 9# | 10.78 | 1.00 | 9.98 | 1.6 | |

| 总计 | 97.58 | 27.46 | 108.84 | 14.6 | |

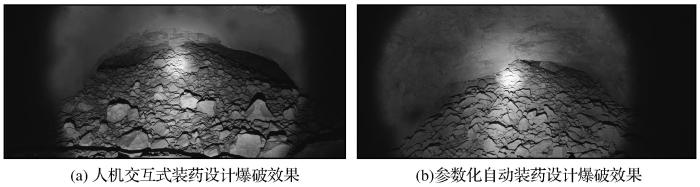

以相同地质及装药条件的2次爆破试验为例,爆破结果如图10所示。

图10

图10

2种装药设计方案爆破结果对比

Fig.10

Comparison of blasting effect of two charging design schemes

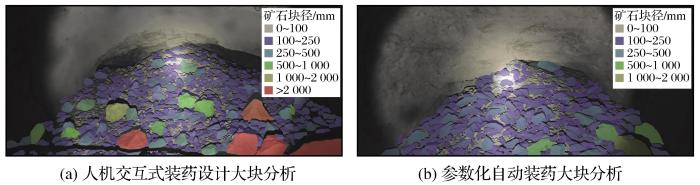

图11

图11

2种装药设计方案块度分析对比

Fig.11

Comparison of block size analysis of two charge design schemes

根据现场矿石破碎要求,将块径500 mm以上的矿石认定为大块。图11所示的表面爆堆图像显示,采用参数化装药设计现场出矿大块率明显低于人机交互式装药设计。另外,采用参数化装药设计时间极大地缩短,从4 h减少至5 min。相比于人机交互式布孔需花费4 h,本文方法在有效改善爆破效果的同时,极大地提高了装药设计效率。

4 结语

(1)基于爆破范围离散化设计思想,构建了以装药量与担负矿量逻辑性约束、炮孔间装药结构互斥性约束及总装药量与装药单耗相匹配约束等为约束条件,以各项约束条件下装药结构的爆破影响范围最大为目标的地下矿扇形中深孔装药设计优化数学模型。

(2)将提出的地下矿扇形中深孔装药设计方法应用于某矿山。试验结果表明,相似地质条件和装药条件下2次爆破试验采用参数化装药设计时现场出矿大块率明显低于人机交互式装药设计,装药设计时间极大地缩短,从4 h减少至5 min。由此可见,地下矿扇形中深孔参数化装药设计方法最大程度地保障了炮孔间装药能量分布均匀性,保证了爆破质量,且装药设计时间大幅缩短,极大地降低了采矿设计技术人员工作量,提高了设计工作效率。

http://www.goldsci.ac.cn/article/2024/1005-2518/1005-2518-2024-32-6-1107.shtml

参考文献

Mid-deep hole cutting blasting technology based on slit charge directional presplitting

[J].

Refined design and optimization of underground medium and long hole blasting parameters—A case study of the Gaofeng mine

[J].

Empirical approach based estimation of charge factor and dimensional parameters in underground blasting

[J].

Effect of uncoupled charge coefficients on rock blast damage

[J].

Design and application of parameters of medium and deep hole blasting in underground quarry

[J].

Optimization design of fan-shaped medium-deep hole blasting hole placement based on floyd algorithm

[J].

Study on the distribution characteristics of deep hole blasting in the fan-shaped hole of Shilu iron mine

[J].

Application of downward fan-shaped medium and deep hole blasting in Sanshandao gold mine

[J].

Three-dimensional blasting design for underground mines

[J].

Research on the generation mechanism and control of large chunks of falling ore by fan-hole blasting

[J].

Optimized design of blasting based on the correlation study of medium and deep hole blasting parameters in underground mines

[J].

Research on parameters of deep hole blasting in deep large section hard rock tunneling

[J].

Research on the application of medium and deep hole blasting technology in underground iron ore mining

[J].

Research and pra-ctice of underground medium and deep hole large-scale bla-sting

[J].

Development and application of intelligent design system for fan-shaped medium-deep hole blasting in underground mines

[J].

Numerical simulation analysis of blast damage range

[J].

Research on block size control technology of medium-deep hole-fall blasting in underground mines

[J].

Numerical simulation study on the influence law of explosives unit consumption on the block size of hematite blasting

[J].

Intelligent identification of large diameter deep hole blasting parameters to assist design

[J].

Improvement of the effect of medium and deep hole blasting in production

[J].

基于切缝装药定向预裂的中深孔掏槽爆破研究

[J].

不耦合装药系数对岩体爆破损伤的影响

[J].

地下采场中深孔爆破参数设计与应用

[J].

基于floyd算法的扇形中深孔爆破布孔优化设计

[J].

石禄铁矿扇形中深孔爆破块度分布特征研究

[J].

基于地下矿中深孔爆破参数相关性研究的爆破优化设计

[J].

下向扇形中深孔爆破在三山岛金矿的应用

[J].

地下矿山三维爆破设计

[J].

扇形孔爆破落矿大块产生机理及控制研究

[J].

深部大断面硬岩巷道掘进中深孔爆破参数研究

[J].

中深孔爆破技术在井下铁矿开采中的应用研究

[J].

地下中深孔大规模爆破的研究与实践

[J].

地下矿扇形中深孔爆破智能设计系统的开发与应用

[J].

爆破损伤范围数值模拟分析

[J].

地下矿山中深孔落矿爆破块度控制技术研究

[J].

炸药单耗对赤铁矿爆破块度的影响规律数值模拟研究

[J].

大直径深孔爆破参数智能识别辅助设计

[J].

中深孔爆破在生产中效果的改善

[J].

甘公网安备 62010202000672号

甘公网安备 62010202000672号